What is Digital Fabrication and Its Usage?

Table of Contents

What Is Digital Fabrication?

Digital fabrication is a computer-controlled design and manufacturing process where the digital data, in the form of a CAD file, defines the instruction to the fabrication equipment to produce the output. The CAD data usually becomes the axis coordinates that move the equipment arm. The process can be either subtractive or additive or even robotic automation. Regardless of the type, it allows architects, designers and engineers to create and test prototypes as well as mass production. Though it is not a new technology, it is still being explored and developed for a more controlled and efficient production process. Digital fabrication has long been used in manufacturing industries but now architects and many other professionals are embracing this brilliant technology.

Evolution of Digital Fabrication

While it is unclear when the term first appeared, we know that MIT created the first computer-controlled milling machine in 1952. Fast forward a few years to 1986, Charles Hull co-founded 3D Systems and commercialized his 3D printing technology, or stereolithography, along with the STL file format that translated CAD data for 3D printing. And it became the first commercial rapid prototyping fabrication technology. Since then, the digital fabrication technology has evolved into a variety of additive and subtractive manufacturing processes. We will talk about these processes later in this guide.

What Does the Process Involve?

A precise CAD drawing is perhaps the most important part about the fabrication process as it is the input data to the equipment. For a simple laser cutting process, a simple 2D drawing may suffice but for other subtractive, and additive, manufacturing processes, 3D components are necessary. In this case, they will be translated into points and edges that are easy to read by the machine.

The CAD file is then converted into a CAM (Computer Aided Manufacturing) file which will guide the equipment nozzle according to the geometry defined in the file. In some equipment, we can adjust the speed of the nozzle or the robotic arm and the feed rate of the material. For example, in a laser cutting tool, we can adjust the distance between the tip of the nozzle and the surface of the material as well as intensity of the laser to achieve the desired outcome. After all, cutting is not the only action possible in this process.

Once you have the CAD file ready, the next step is to determine the best fabrication technology to use. Even in 3D printing, there are a number of different methods to shape an object, all dependent on the 3D model, material used and the desired accuracy of the final output.

Because there is little human activity involved once the CAD file has been sent to the machine, we can leave the machine to see itself through the remaining process.

How Is Digital Fabrication Used In Architecture?

Fabrication was a technology dominated by the manufacturing industry. Architecture is an industry where both design and making (production) happens in a continuous progress of development of concepts and forms. However, most productions were done manually, even the drawings. It wasn’t until the 80s that architects started fully relying on CAD, and it wasn’t until a decade ago that BIM (Building Information Modelling) and computational design came into the picture!

Are you new to BIM? Then Understanding BIM (Building Information Modelling): A Complete Guide is a must-read!

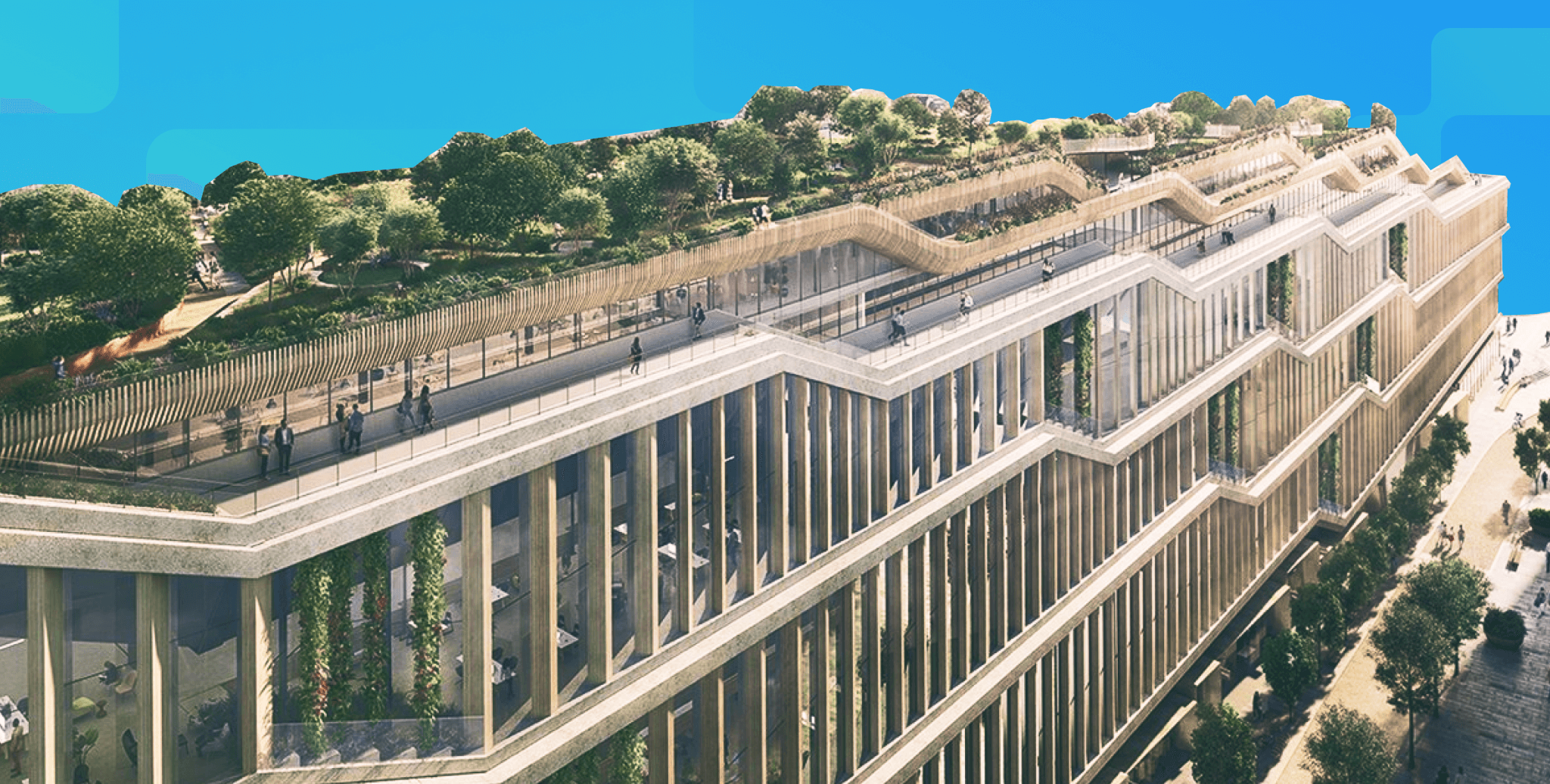

Being a project-based niche, each architectural project and solution are unique. Now, architecture has become fully integrated with digital technologies in both design and construction processes, giving us countless intriguing projects in the built environment .

We can observe the use of digital fabrication technologies in architecture in four ways:

Prefabrication

Prefabrication may just be the more sustainable construction we need today. In this process, parts of a building are constructed off-site, usually in factories, and then assembled on-site. This not only shortens the on-site construction period but also reduces waste and carbon footprint. Moreover, many of these building components constructed in concrete and glass are potentially renewable materials.

Find out more about sustainability in our Ultimate Guide to Sustainable Architecture.

Prototyping

Prototyping is perhaps the earliest and the most common fabrication activity implemented by architects. Usually, the products are small, either a scaled physical model of a building or a building/furniture component. These are easily feasible using 3D printers and laser cutting machines. By having a prototype, we can test joineries, facades and the whole structures and it is a great way to experiment during design development.

Developing and Testing New Materials

A new breakthrough in digital fabrication is the development of new materials for construction. Highly efficient and sustainable, these new and advanced materials will soon become on a par with the traditional materials.

MIT’s Mediated Matter Group is well-known for their groundbreaking research in material development. Rather than focusing on manufacturing, the team of architects, biologists and researchers turns their attention towards science and its significance in fabrication.

How Is Digital Fabrication Used In Engineering?

The role of digital fabrication has been prominent in the engineering industry, far before the architecture industry embraced it. Here are a few popular examples of how the tool is used by engineers!

Automating Construction Using Robotics

Robotic operations are slowly getting tested in the construction industry where the assembly of framed structures and prefabricated materials are done entirely by the robots. Architects and researchers are hopeful that such processes will lead to a more controlled and safer work environment while prompting better productivity.

Better Integrated Design and Construction Stages

CAD, CAM and CAE (Computer aided engineering) have brought design, analysis and manufacturing closer together for safer structural designs and construction. Manufacturing and engineering have always been closely tied together; after all, fabrication itself is an engineering marvel. Thus, in a way, we can say fabrication has also brought engineering and architecture closer together.

Why Do We Need Digital Fabrication?

Digital fabrication has connected design and manufacturing with an improved rate of productivity. The fabrication process is completely automated by computers with minimal human input and is faster and more accurate. This fact alone has defined the first advantage of fabrication - efficiency.

The accuracy means there is little rework needed and less material wasted. Some fabrication materials can be slightly more costly than others since they are less readily available, but if we can reduce the wastage, we can surely also lower the overall cost of fabrication.

The computational process of fabrication is also faster, saving the designers time to manufacture. Most of the fabrication equipment needs little supervision during the process so we can just conveniently work on a new design as we wait!

Needless to say, this also reduces the manpower necessary for fabrication and construction processes. While there are many valid concerns that machines are going to replace craftsmen, it is also an asset to entrepreneurs and new designers who want to explore iterations of design within a limited time span.

In addition to being an efficient means of production, the potential of fabrication is also limitless. Its use was limited to rapid prototyping in the past, but now we can 3D print whole buildings. Even though our dependency on digital fabrication is soaring, this is a technology that is still in development, meaning we can be excited for what fabrication technology will be able to do in the future.

Popular Fabrication Technologies And Equipments

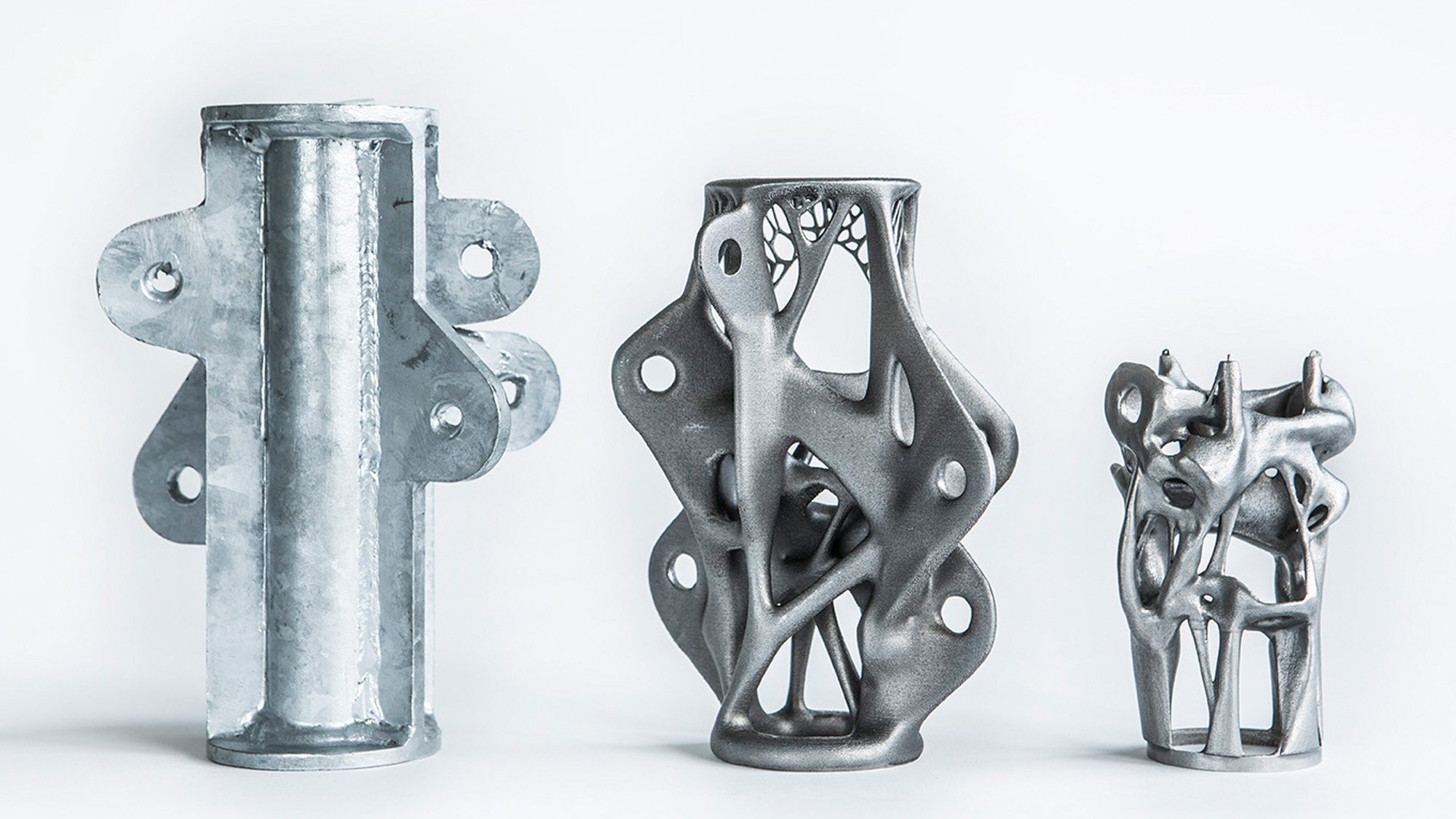

The interest in digital fabrication has naturally encouraged designers and researchers to invent even more diverse technologies. We can generally categorise them into additive and subtractive manufacturing.

Under Additive Manufacturing --

3D Printing - some consider 3D printing synonymous with additive manufacturing. In a typical 3D printing process, the material is melted, deposited through a nozzle onto the base platform layer by layer. The more advanced the software and equipment are, the more accurate the final product will be, and most likely the more expensive it will get. The smaller commercial type 3D printers cost less and are best for rapid prototyping.

-

Binder Jetting - another type of 3D printing, binder jetting uses powder materials and liquid binding agents instead of a melted material. The rest of the process is more or less the same – the nozzle deposits the powder and the binding agent in layers.

Under Subtractive Manufacturing -

-

Laser cutting - this technology has become so common that anyone can make laser-cut products for their business. The high intensity laser beam falls onto the material cutting and/or engraving according to the input CAD file. The depth of it is determined by the laser intensity and the distance of the nozzle.

-

CNC machining - CNC stands for Computer Numerical Control and is a computerized operation that gives shape to the object by removing excess material. CNC machining is actually an umbrella term that includes processes such as milling, drilling, grinding and turning.

The equipment comes in a variety of scales, from small commercial 3D printing machines for hobbyists and small businesses to large-scale industrial equipment. Many design and architecture schools provide at least a 3D printing and a laser cutter for students to get acquainted with these technologies.

Read more in detail about fabrication technologies here - 5 Popular Fabrication Technologies Dominating the Manufacturing Industry

Most Used Fabrication Materials

The technological revolution has brought upon countless innovative elements to the industry, one of which is most important for digital fabrication processes – materials. The materials used can affect the form, production duration, appearance and the functions of the output. Here are some of the best fabrication materials available in the market today:

-

Steel - An alloy of iron and carbon, steel is a common material in our built environment. The steel fabrication gives us building components like universal beams and columns, as well as industrial instruments like skids and ladders.

-

Copper - The fabrication process using copper includes copper sheet metal rolling and bending. This material is frequently used in electrical wiring, telecommunication cables and gutters. It is malleable, conductive, corrosion resistant and economical.

-

Thermoplastics - One of the most common fabrication materials used in digital fabrication, thermoplastics are versatile, recyclable and cost-effective. We can find this material in chemical storage vessels, pipelines and ductworks.

-

Wood - Digital fabrication has enhanced the beauty and versatility of wood and given us many wonderful products. We can laser-cut wood panels and pallets to precision to create furniture and installation. ‘Please Be Seated’ project and Plexus Pavilion are great examples of digitally fabricated parametric furniture.

Read more about fabrication materials in our blog - List of Top Fabrication Materials to Use in the Construction Industry Today

Digital fabrication is both an old and new technology that brings so many exciting potentials for the AEC industry. Many architects and designers have welcomed it as part of the necessary step to explore their creativity. We can now 3D print a whole house. What do you think is next?

If you enjoy reading our informative guides, find more of them on our Resources page.

In addition, you can also check out our Instagram and YouTube channel for more updates on what’s hot and trending in the AEC industry.

Thanks for connecting!

Thanks for connecting!

%20(1).png)

%20(1).png?width=767&height=168&name=MCD%20B%20(Course%20Banner)%20(1).png)

/fit-in/1536x864/images/blog/blogHero/Building_with_greenry.jpg)

/fit-in/1536x864/images/blog/blogHero/BIM_model_different_stages.jpg)

/fit-in/1536x864/images/blog/blogHero/Rain_Watcher_Catcher_NUDES_Office.jpg)

.png)

%20-%202023.jpg)

.jpg)