.png)

Let us face it, MEP design can be a bit of a minefield. Whether you are a seasoned MEP design engineer or just stepping into the dynamic world of the MEP industry, you have probably encountered a fair share of hurdles. From miscalculations in duct sizing to clashes between systems, MEP issues can sneak up in the most unexpected ways. The consequences? Delayed timelines, budget overruns, and a lot of head-scratching during the construction phase.

In this blog, we will walk you through the most common MEP design mistake scenarios, how they can be avoided, and how smart planning (and even smarter tech) can keep your projects running smoothly.

Why Is Accurate MEP Design Crucial in Construction Projects?

So, what is MEP design exactly? For those who might be new, MEP design stands for Mechanical, Electrical, and Plumbing design. These systems form the backbone of any modern building. Think of them as the hidden machinery that keeps our lights on, air clean, and water flowing. Inaccurate or poorly thought-out MEP design can have a domino effect on the rest of the build, leading to a range of MEP issues from overheated equipment rooms to improperly ventilated spaces.

With the increasing complexity of modern MEP systems, especially in large-scale commercial or residential developments, the role of a MEP design engineer has become more critical than ever. And with a surge in demand for professionals in MEP jobs, mastering good design principles is not just smart—it is essential.

Top 10 Common MEP Design Mistakes and How to Avoid Them

1. Lack of Coordination Between Disciplines

Mistake:

Ignoring the need for collaboration between mechanical, electrical, and plumbing systems leads to clashes and conflicts during construction.

Solution:

Implement clear communication channels, hold regular project meetings, and utilise collaboration tools like BIM 360 to ensure all disciplines work on a centralised model. Coordination is the backbone of integrated MEP design, and early detection of overlaps can save both time and money.

2. Inadequate Space Planning

Mistake:

Not allocating sufficient space for MEP equipment can lead to cramped layouts, service access issues, and expensive redesigns.

Solution:

Always account for installation and future serviceability of MEP infrastructure. Early planning using MEP BIM modelling enables accurate space allocation and keeps the architectural intent intact while allowing sufficient clearance around systems.

3. Overlooking Equipment Maintenance Access

Mistake:

Designing systems without considering how technicians will maintain or replace MEP equipment is a common but preventable error.

Solution:

Add service corridors and hatches to your model. Remember, if a part cannot be accessed for maintenance, it will be neglected, which will compromise the efficiency and lifespan of your MEP systems.

Also Read: Top 10 Trends in MEP Design

4. Relying Solely on 2D Drawings

Mistake:

2D plans can be misleading, making it easy to miss potential clashes or spatial constraints within MEP systems.

Solution:

Step into the 3D world! Leverage Revit MEP and BIM software to create a detailed digital twin of your project. This allows you to test, review, and refine your design long before site work begins.

5. Incomplete Load Calculations

Mistake:

Incorrect HVAC or electrical load estimations can result in undersized systems and future performance issues.

Solution:

Use reliable MEP design software to run detailed simulations for cooling, heating, and power loads. Integrate these calculations with MEP software to model real-world performance under varied conditions.

6. Ignoring Local Codes and Standards

Mistake:

Non-compliance with local building codes can cause legal delays, penalties, or even reconstruction.

Solution:

Stay informed about the legal landscape of MEP in building construction. Integrate relevant standards into your MEP design services from day one to avoid unpleasant surprises down the road.

7. Late Involvement of MEP Consultants

Mistake:

Bringing in MEP design engineers after the architectural design is finalised often results in rework and clashes.

Solution:

Involve your MEP design services from the conceptual design phase. Their input can influence decisions about ceiling heights, wall chases, and utility cores that are crucial for MEP works in construction.

8. Poorly Designed Duct and Pipe Routing

Mistake:

Unplanned duct and pipe runs can reduce system efficiency and conflict with structural elements.

Solution:

Use Revit MEP software and intelligent MEP design software to optimise routing. Good routing saves space, reduces energy loss, and simplifies MEP construction management.

9. Neglecting Integration with Smart Systems

Mistake:

Failing to plan for smart controls and data collection can lead to costly retrofitting.

Solution:

Design for the future. Ensure your MEP systems can integrate with IoT platforms and automation technologies. This requires close coordination with IT and facilities management teams early in the design.

10. Underestimating Energy Efficiency

Mistake:

A lack of focus on energy performance can impact operational costs and sustainability ratings.

Solution:

Simulate energy usage patterns using BIM software and adopt eco-friendly solutions like demand-based ventilation and LED lighting. Sustainability is not just a buzzword, it is a client expectation.

Also Read: Top 50 MEP Interview Questions & Answers 2026

How BIM Helps Prevent MEP Design Errors

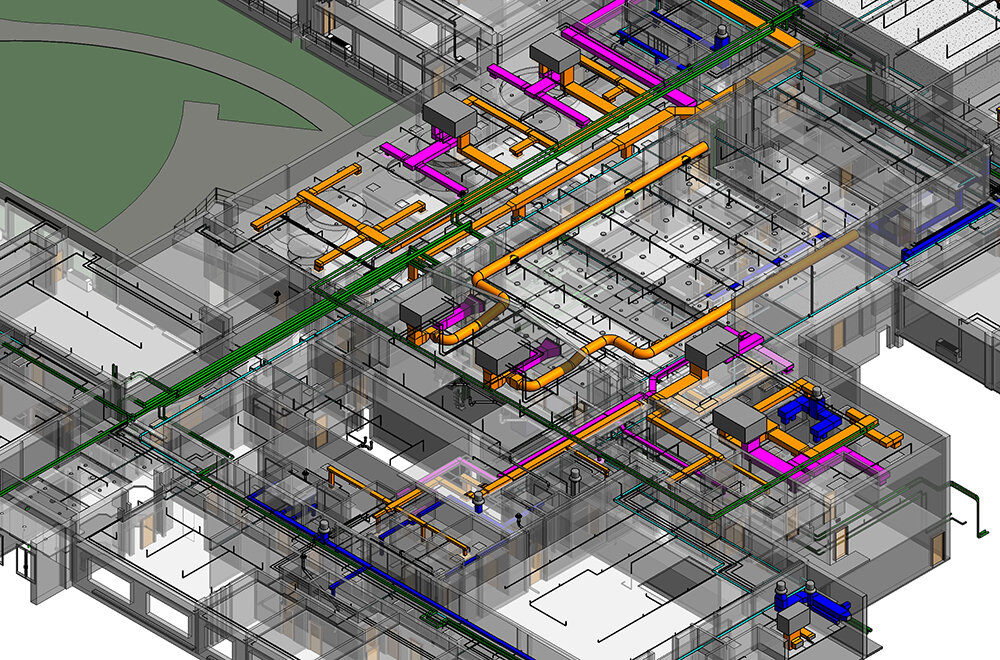

Building Information Modelling, or BIM software, has revolutionised the way MEP design engineers approach complex projects. Instead of relying on fragmented 2D drawings or disconnected software tools, BIM creates a fully integrated digital representation of all MEP systems By visualising every pipe, duct, cable, and piece of MEP equipment in a shared environment, BIM not only minimises errors but also improves efficiency, reduces waste, and enhances overall project quality.

Here are some important ways BIM helps prevent MEP design mistakes:

1. Early Clash Detection

Using Revit MEP and other MEP BIM modelling tools, BIM allows engineers to run clash detection reports that flag collisions between mechanical, electrical, and plumbing systems, saving costly rework on site.

2. Improved Coordination

BIM facilitates real-time collaboration among architects, structural engineers, and MEP design engineers by providing a centralised model that everyone updates and reviews, reducing miscommunication.

3. Accurate Quantity Takeoffs

BIM automates the generation of material quantities for MEP equipment and components, leading to more precise procurement and budgeting.

4. Enhanced Visualisation

Three-dimensional models help all stakeholders better understand complex layouts, making it easier to review and approve MEP infrastructure before installation.

5. Scenario Simulation

BIM enables running simulations to test HVAC airflow, electrical load distribution, and plumbing hydraulics, ensuring optimal system performance.

6. Streamlined Changes

When modifications are needed, BIM ensures that updates propagate throughout the model instantly, keeping drawings, schedules, and reports consistent.

7. Sustainability Analysis

Integration with energy modelling tools within BIM helps evaluate designs for energy efficiency, contributing to greener buildings.

8. Improved Construction Planning

BIM supports MEP construction management by simulating installation sequences and logistics, reducing delays and clashes on site.

Also Read: BIM for MEP: A Complete Guide 2026

Conclusion

Avoiding a MEP design mistake is not about being perfect; it is about being prepared. From smart planning to adopting powerful tools like Revit MEP, the difference between costly errors and construction success often lies in the details. Equip yourself with the right strategies and software, and those dreaded MEP issues will be a thing of the past.

You should consider checking the BIM Professional Program for MEP Engineers by Novatr. Check out the Resources Page at Novatr for the most recent information, resources, and insights into the MEP and BIM sectors.

Was this content helpful to you

.jpeg)

.png)