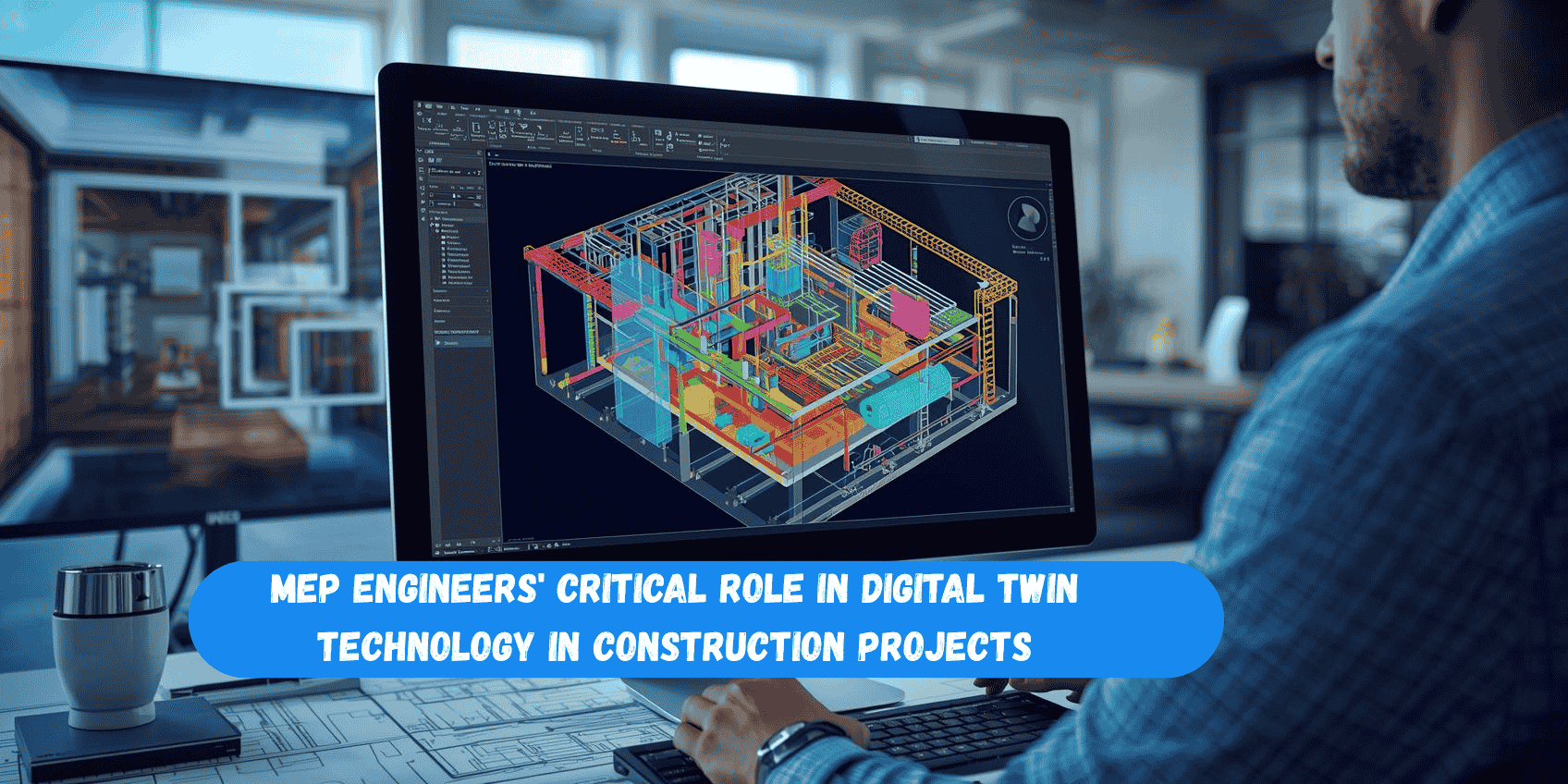

The construction industry is undergoing a digital revolution, and at its heart lies Digital Twin technology. But what is a Digital Twin?

By creating a dynamic, virtual representation of physical assets, a Digital Twin enables better design, monitoring, and management of buildings throughout their lifecycle. While architects and structural engineers play important roles, it is the MEP engineers (Mechanical, Electrical, and Plumbing) who are central to making these digital replicas truly functional. Their expertise ensures that the lifelines of a building, including its energy systems, water supply, HVAC, and electrical infrastructure, are accurately modelled, monitored, and optimised in real-time. This makes MEP engineers indispensable in shaping the future of smart, sustainable, and resilient buildings.

What is Digital Twin Technology?

Digital Twin technology refers to the creation of a virtual model that mirrors a physical building, infrastructure, or system. Unlike static 3D models, the technology is dynamic, continuously updated with real-time data from sensors, IoT devices, and building management systems.

How does a Digital Twin work? They allow stakeholders not only to visualise but also to monitor, analyse, and predict the performance of a structure throughout its lifecycle.

For construction projects, Digital Twin benefits include enhanced design validation, streamlined construction sequencing, and predictive maintenance once the building is operational.

For example, a Digital Twin of an HVAC system can track energy usage, detect anomalies, and predict when equipment might fail. Similarly, a Digital Twin for plumbing can monitor water consumption patterns and detect leaks early. The technology creates an ecosystem where physical and digital environments interact seamlessly, empowering facility managers, contractors, and owners to make data-driven decisions.

Why are MEP Engineers Crucial for Implementing Digital Twin Technology?

What is MEP engineering? It is the field that deals with mechanical, electrical, and plumbing systems, making buildings safe, habitable, and efficient. These systems, heating, cooling, lighting, power distribution, and plumbing, are also the most dependent on real-time performance monitoring. Without the active participation of MEP engineers, a Digital Twin would merely be a structural model, lacking the operational intelligence that sets it apart.

The roles of a MEP engineer in construction include providing the technical data and system logic required to create functional digital representations. For instance, they define sensor placements, determine which data streams are critical, and configure how systems should respond to certain conditions. Their expertise ensures that the impact of MEP engineering on Digital Twin efficiency is maximised by capturing the complexities of energy flow, ventilation, and water distribution.

Moreover, professionals play a crucial role in integrating the Digital Twin with BIM for MEP engineers. While BIM provides detailed layouts, MEP engineers support building Digital Twin by embedding performance data and operational logic. This integration transforms BIM into a true Digital Twin that supports both design and lifecycle management.

Also Read: How Project-Based Learning Helps You Build a Strong Portfolio for MEP Engineers

How Do MEP Engineers Contribute to Creating Accurate, Real-Time Digital Representations?

The accuracy and usefulness of a Digital Twin depend heavily on the input and oversight of MEP engineers. The duties of an MEP engineer include ensuring that every system, be it mechanical, electrical, or plumbing, is modelled not just in form but also in function. By collaborating with technology experts, they map physical assets to their digital counterparts with precision.

For example, in HVAC systems, MEP engineers calibrate the Digital Twin to replicate airflows, temperature variations, and energy consumption under different conditions. Electrical engineers configure the twin to track power loads, renewable energy integration, and backup systems. Plumbing engineers design models that replicate water pressure, flow rates, and waste management systems. These inputs, combined with IoT-enabled sensors, create real-time feedback loops.

Additionally, MEP engineers help establish parameters for predictive analytics. By defining acceptable ranges for performance, they enable the Digital Twin to issue alerts when deviations occur. This proactive monitoring highlights the importance of MEP engineers for Digital Twin integration, reducing downtime, enhancing safety, and lowering maintenance costs.

Which MEP Systems are Most Important for Digital Twin Models?

1. HVAC Systems:

-

Accurate mechanical modelling ensures energy-efficient HVAC systems operation.

-

Enables predictive maintenance, airflow optimisation, and real-time performance monitoring.

-

BIM for HVAC design integrates HVAC into the building's Digital Twin for coordinated system management.

2. Electrical Systems:

-

Critical for power stability, load management, and renewable energy integration.

-

Digital Twin models help simulate energy consumption and prevent outages.

-

Ensures seamless HVAC integration with MEP building services and facility safety.

3. Plumbing Systems:

-

Tracks water usage, detects leaks, and improves overall water efficiency.

-

Supports sustainability goals through predictive maintenance and resource management.

-

Plumbing Digital Twins contribute to the long-term reliability of MEP engineering systems.

4. Coordination Across Systems:

-

MEP engineers synchronise HVAC, electrical, and plumbing systems to maximise Digital Twin accuracy.

-

Ensures benefits extend to indoor comfort, occupant safety, and operational efficiency.

-

Demonstrates how MEP engineers create Digital Twin models to make them a holistic management tool.

Also Read: Top 50 MEP Interview Questions & Answers 2026

Which Industries and Projects Benefit the Most from MEP-Driven Digital Twin Solutions?

1. Commercial Buildings:

-

Use Digital Twin for energy optimisation, HVAC scheduling, and electrical load balancing.

-

HVAC BIM in construction ensures real-time performance and efficiency tracking.

2. Hospitals and Safety-Critical Facilities:

-

Digital Twins monitor HVAC, electrical, and plumbing systems for uninterrupted safety compliance.

-

MEP engineers simulate emergency scenarios and ensure system resilience.

3. Industrial Facilities:

-

Balance ventilation, cooling, and equipment load through HVAC coordination BIM.

-

Optimise production environments while minimising energy consumption.

4. Infrastructure Projects:

-

Airports, metros, and transit hubs rely on MEP Digital Twin for system coordination and predictive maintenance.

-

Ensures safety, efficiency, and operational continuity.

5. Residential and Luxury Projects:

-

Smart homes integrate energy-efficient HVAC systems and plumbing controls into Digital Twin models.

-

Supports sustainable living and net-zero building goals.

-

Demonstrates the value of MEP engineering in creating intelligent, responsive living environments.

Conclusion

Digital Twin technology is revolutionising the design, construction, and operation of buildings. At the core of this transformation are MEP engineers, whose expertise ensures that Digital Twins are accurate, responsive, and valuable throughout a building’s lifecycle.

From predictive maintenance to sustainability and energy efficiency, the roles of a MEP engineer in construction are fundamental.

The roles of a MEP engineer in construction, pursuing MEP jobs, offer an exciting future. An MEP engineer's career path involves working on cutting-edge projects that utilise technologies such as Digital Twins and BIM. The MEP engineer job description now extends beyond design; it includes enabling smart, data-driven, and sustainable construction.

Ultimately, the importance of MEP engineers for Digital Twin integration cannot be overstated. By leveraging Digital Twin technology, MEP engineers are not just designing systems; they are shaping the future of smarter, greener construction.

For professionals aspiring to build a career in this cutting-edge space, Novatr’s BIM Course for MEP Engineers offers the perfect launchpad. It’s not just a course, it’s a pathway to becoming an industry-ready MEP engineer in the age of smart construction. For more insights, head to our Resources page.

FAQs

1. What is a Digital Twin in construction and building management?

A Digital Twin is a dynamic, real-time virtual model of a building that integrates design, performance, and operational data seamlessly.

2. How do MEP engineers contribute to creating an accurate Digital Twin?

MEP engineers design, simulate, and integrate mechanical, electrical, and plumbing systems into digital models, ensuring real-time accuracy and system performance monitoring.

3. Can a Digital Twin function effectively without detailed MEP input?

No, without detailed MEP input, a Digital Twin lacks crucial building system intelligence, reducing functionality, predictive accuracy, and lifecycle management value.

Was this content helpful to you

.png)