.png)

Construction methods are evolving to meet tighter schedules and complex project demands, emphasizing precision and coordination. With MEP prefabrication in construction, components can be assembled off-site, minimizing delays and reducing errors. This approach improves workflow and installation accuracy, while construction engineers in the USA earn an average salary of $88,563/year, reflecting the expertise required in managing such projects.

As projects become more complex, adopting modular strategies helps streamline coordination and simplify challenging workflows. A revolution in MEP construction is emerging, with standardized off-site processes reducing errors, accelerating schedules, and improving overall efficiency. These methods support better cost management and resource allocation, providing a reliable approach that enhances both project predictability and execution quality.

What Are Modular MEP Systems And How Do They Differ From Traditional Methods?

Modular MEP systems are pre-engineered, standardized units for mechanical, electrical, and plumbing components designed to integrate seamlessly into construction projects. Unlike conventional approaches, they emphasize coordinated planning, quality control, and faster deployment. Their ability to reduce on-site complexity, improve predictability, and enhance overall project efficiency is what makes modular MEP systems important in modern construction and supports more reliable, streamlined project execution.

Key distinctions between modular and traditional MEP methods include:

-

Collaborative Design: Components are planned across all disciplines from the start, reducing conflicts, unlike traditional methods where planning is often done separately.

-

Prefabricated MEP Systems: Modules are created and tested off-site, ensuring consistent quality, while conventional systems rely on on-site fabrication and adjustments.

-

Streamlined Installation: Modular units arrive ready to assemble, simplifying construction, whereas traditional methods require sequential on-site assembly.

-

Standardized Layouts: Designs follow pre-defined configurations for efficiency, in contrast to custom, site-specific solutions used in conventional systems.

-

Pre-verified Testing: Detailed quality checks and documentation are completed before delivery, unlike traditional approaches that may need iterative on-site corrections.

Why Are Modular MEP Systems Becoming a Game-Changer in Modern Construction?

Modular MEP systems are playing an increasingly vital role in managing complex construction projects and meeting tighter timelines. One key reason why prefabricated MEP systems are gaining popularity is that modular approaches provide structured planning, consistent processes, and greater predictability. In this context, these methods reflect the growing need for reliable, efficient construction practices without relying on fragmented traditional approaches.

The following aspects illustrate the ways modular MEP systems are transforming modern construction:

-

Modular MEP adoption improves project predictability by integrating design, fabrication, and scheduling processes more effectively than traditional methods.

-

Off-site preparation reduces on-site conflicts, ensuring smoother assembly and minimizing the risk of delays.

-

Reusable and standardized components simplify coordination between contractors, engineers, and stakeholders across large-scale projects.

-

Digital modeling and planning tools enhance accuracy, supporting complex projects while reducing errors and rework.

-

Faster installation timelines, improved labor allocation, and streamlined resource management illustrate how offsite MEP prefabrication supports efficiency.

Also Read: Who is a MEP Engineer? (Skills, Qualifications, Scope & More)

What Benefits Do They Offer in Terms of Time, Cost, and Project Efficiency?

Modern construction demands methods that optimize workflow, reduce uncertainty, and improve overall coordination across teams and systems. Modular MEP systems are increasingly recognized for addressing these requirements, supporting streamlined planning, and enhancing operational control. Their growing relevance in meeting project objectives efficiently demonstrates how modular MEP improves project delivery and timelines.

The following key aspects highlight how modular MEP systems contribute to enhanced project efficiency, cost management, and schedule adherence:

-

Accelerated installation allows multiple construction activities to proceed simultaneously, shortening overall project timelines.

-

Pre-engineered components reduce errors and minimize the need for on-site adjustments, ensuring more accurate execution.

-

Streamlined coordination between contractors, engineers, and suppliers improves resource allocation and reduces idle time.

-

Integration with digital planning tools supports precise scheduling, progress tracking, and risk management throughout the project.

-

Pre-assembled units, optimized labor use, and minimized material waste demonstrate how modular MEP reduces construction errors and costs.

What Challenges Exist in Adopting Modular MEP Systems Across Industries?

Adopting modular MEP systems across industries presents a variety of challenges that require careful consideration and planning. While these systems offer efficiency and standardization, their implementation can be hindered by technical, logistical, and organizational factors. Successful integration demands skilled personnel, coordination among stakeholders, and alignment with existing practices, making MEP engineering expertise critical in addressing these adoption hurdles effectively across diverse construction environments.

The following points highlight key challenges encountered during adoption:

-

Initial Investment Costs: High upfront costs for prefabrication facilities and specialized equipment can deter organizations from transitioning to modular MEP systems.

-

Skilled Workforce Requirements: Adequate training and expertise are necessary to manage design, fabrication, and installation processes effectively.

-

Design Standardization: Achieving uniformity across different projects can be challenging when adapting modular systems to diverse building specifications.

-

Logistical Coordination: Transporting and handling pre-assembled modules requires careful planning, especially for large or complex components.

-

Integration with Existing Systems: Ensuring modular MEP systems align with conventional construction processes can require additional adjustments and planning.

-

Regulatory and Compliance Issues: Navigating varying local codes, standards, and approvals can delay adoption and complicate project timelines, highlighting the importance of modular MEP engineering expertise.

How Does BIM Support the Design, Coordination, and Installation of Modular MEP Solutions?

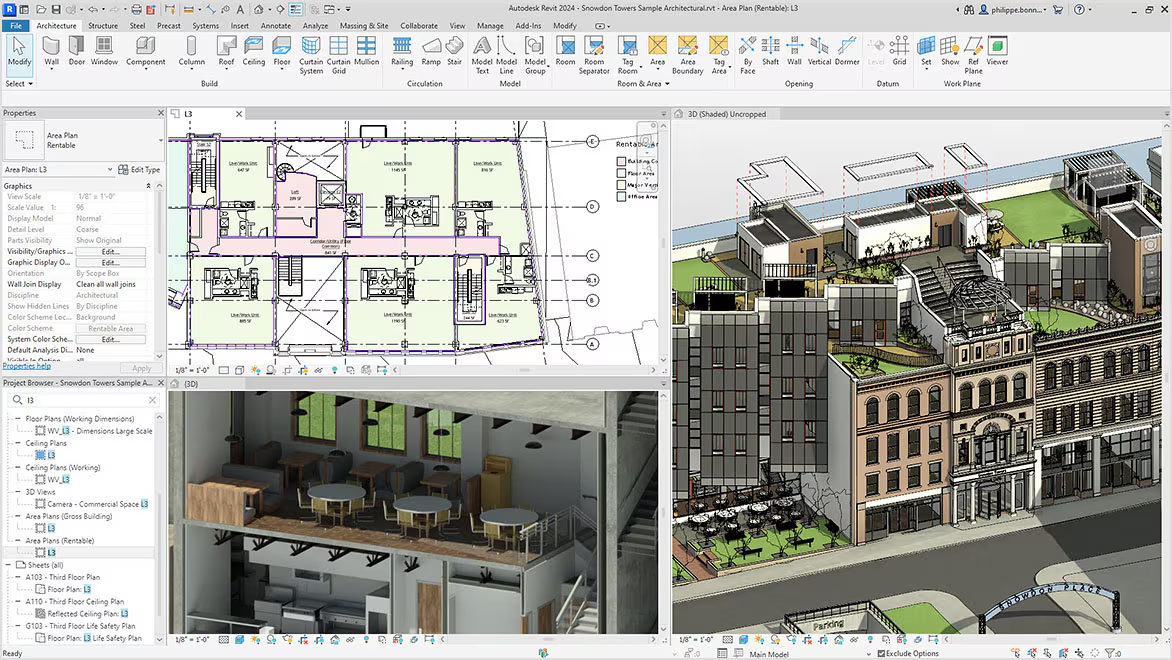

Building Information Modeling (BIM) plays a pivotal role in modern construction by improving visualization, collaboration, and planning for complex systems. It allows teams to anticipate potential conflicts, optimize designs, and streamline workflows. Expertise in BIM for MEP engineers is essential to fully leverage these tools, enabling precise coordination and facilitating the seamless integration of modular MEP solutions across diverse projects.

Here are key ways BIM supports modular MEP design, coordination, and installation:

-

Enhanced Visualization: 3D models provide a clear representation of mechanical, electrical, and plumbing layouts, reducing misunderstandings among teams.

-

Clash Detection: BIM identifies potential conflicts between systems before construction begins, preventing costly rework.

-

Design Optimization: Iterative modeling allows engineers to refine layouts for efficiency, space utilization, and performance.

-

Improved Collaboration: Centralized digital models facilitate coordination between architects, contractors, and engineers, ensuring all stakeholders are aligned.

-

Installation Planning: Detailed sequencing and construction simulations allow teams to schedule and manage on-site installation efficiently.

-

Integration with Tools: Use of specialized MEP software within BIM enhances precision, documentation, and system performance analysis.

Conclusion

Modern construction increasingly relies on integrated, pre-planned approaches to manage complexity, timelines, and coordination challenges effectively. Organizations that adopt such structured methods benefit from improved operational control, reduced errors, and better alignment across multiple teams, supporting consistent and reliable project outcomes.

For those looking to strengthen technical expertise and practical skills, the BIM Course for MEP Engineers offered by Novatr provides focused learning on planning, coordination, and modular system integration. Visit our resource page to explore more insights, access tools, and gain guidance on implementing advanced strategies that improve efficiency, collaboration, and overall project management in construction projects.

FAQs

1. How do modular MEP systems differ from traditional methods?

Ans: Modular MEP systems differ from traditional methods by using pre-engineered, standardized components built off-site. This approach allows quicker installation, improved coordination, and fewer on-site modifications compared to conventional setups.

2. What are the key benefits of modular MEP systems?

Ans: The key benefits of modular MEP systems include reduced costs, improved quality, faster delivery, and better project coordination.

3. How do modular systems reduce construction time?

Ans: Modular systems reduce construction time by enabling off-site fabrication and simultaneous on-site preparation.

Was this content helpful to you

.jpg)

.png)

.png)