10 Technology Trends For The Construction Industry in 2026

Table of Contents

The construction industry is no stranger to technological innovation, and today it is experiencing a wave of emerging technologies that promise to transform the way things are built. From advanced robotics and 3D printing to augmented reality and the Internet of Things (IoT), the industry is embracing new tools and processes that are improving safety, efficiency, and sustainability. In this blog, we'll take a look at six of the most exciting emerging technologies in the construction industry today and explore how they are revolutionizing the way we design, build, and maintain the structures that shape our world.

Latest Trends in Construction Technology

1. Building Information Modelling (BIM)

One of the most unarguably popular technologies is Building Information Modelling (BIM) – a digital process that involves creating a 3D model of a building and its components, which can be used for design, construction, and maintenance purposes. BIM allows architects, engineers, and contractors to collaborate and coordinate their efforts more effectively, reducing errors, and improving efficiency. In the last decade, BIM has become an essential tool in the construction industry, improving productivity, quality, and sustainability.

For instance, BIM was extensively used in the creation of the Shanghai Tower, an internationally recognised architectural project and an exemplar for BIM projects, owing to its status as one of the tallest and greenest skyscrapers in the world. More than 30 AEC consulting firms were involved in the project, with dozens of subcontractors and extended design project teams responsible for specific areas of the enormous skyscraper. They utilized BIM to achieve the intense coordination required to see the project to fruition.

Applications

- Information is easier to share, add value to, and reuse.

- Architectural concepts can be thoroughly studied, simulations made to run fast, and performance benchmarked, allowing for improved and creative solutions.

- Environmental performance is more foreseeable and lifecycle costs are better understood.

Challenges

- Staff with limited qualifications or knowledge to seamlessly integrate BIM and construction projects.

- Switching to BIM does cost money for software, education, and time. The fact that the potential advantages outweigh the expenses is something to consider, though.

- Management of the workload of the BIM project team.

2. Prefabrication

Prefabrication, also known as modular construction, essentially means creating buildings or building components at a location other than the job site. This method has gained popularity in the construction industry due to its ability to reduce construction time, minimize waste, and increase quality control. Prefabrication can be used in various construction projects such as housing, offices, schools, and hospitals. The building components can be prefabricated off-site and then assembled quickly on-site, reducing disruption to the surrounding area. This approach also allows for a more accurate timeline for project completion, as the time spent on-site is significantly reduced.

Applications

- Factory tolerances and workmanship are higher in quality and consistency than on-site work.

- There is typically less waste.

- Independence from inclement weather and winter working conditions.

Challenges

- Local prefab facilities and a trained workforce to install prefab components are both available.

- The project delivery method prevents effective prefab planning; prefab does not apply to project types.

3. Drone Technology

Drones are among the most cutting-edge construction tools, offering a wide range of applications in construction, such as surveying land, mapping sites, inspecting structures, and monitoring project progress. They can conduct site surveys faster and more accurately than a ground crew, and they are less expensive than aerial imaging. They can also be equipped with various sensors to collect data on environmental factors like temperature, humidity, and air quality. By providing accurate and timely information, drones can help construction teams make more informed decisions, improve safety, and reduce project costs.

- Photogrammetry provides real-world insights

- Image acquisition that is quick, repeatable, and on-demand

- Improved documentation and faster subcontractor reconciliation

- Remote access to the site to check on its current status

Challenges

- Lack of adoption or inertia in implementation due to unfamiliarity, limited

knowledge, privacy concerns, and security concerns

4. 3D Printing

3D printing technology has started to revolutionize the construction industry by providing an alternative method of construction that is more sustainable, efficient, and cost-effective. This technology allows for the creation of large-scale objects using a layer-by-layer approach, which makes it ideal for creating complex architectural designs and geometric shapes. 3D printing can be used to create concrete and other building materials, such as steel and plastic. This allows you to obtain materials more quickly and streamline the process by eliminating unnecessary steps in the middle. 3D printing also allows for printing materials on-site, reducing waste and saving money on transportation and storage.

Curious about robotic elements that enable 3D printing?

Check out: How Automation in Construction is Leading the Way for the AEC Industry

Recently, a three-story apartment building in Wallhausen, Germany was designed and built using COBOD's 3D printer. It stands currently as the tallest 3D-printed residential building (most 3D-printed homes are only one story). This project was printed on-site, therefore there were no individual parts that needed to be sent and assembled, unlike some other like-sized ambitious projects. This resulted in financial savings and also made the project more environmentally and sustainably friendly because there was no need for shipment.

Applications

- Construction sites typically generate a lot of waste, but 3D printers use only the materials needed to build something, resulting in almost no waste.

- 3D printers use materials to create lattice patterns, so recycled plastic can be used to create a strong structure.

- While traditional construction methods involve reusing plans and templates, 3D printing creates unique solutions.

Challenges

- 3D printers are expensive, and the purchase price does not include materials or maintenance.

- Finding qualified workers to work in 3D printing, and construction environments may become even more difficult in the future.

- Quality in 3D printing could become a costly mess if not constantly monitored.

5. Internet of Things (IoT)

IoT, or the Internet of Things, is a technology that gathers data from several linked devices using sensors and algorithms. Such data benefits the construction industry and allows professionals to spot safety concerns and confirm that construction is proceeding according to schedule. Thanks to sensors, real-time data is now available to construction companies, allowing them to act swiftly and expertly.

Applications

- Workers can be warned if they get too close to a dangerous area using wearables designed to prevent injuries. One company that creates equipment that employees can wear is Smartcap.

- Using IoT software and techniques, the connected and monitored equipment may follow pressure, temperature, and humidity calculations to alert them of any potential danger that necessitates prompt action.

- It can be used to instantly map out the construction site.

Challenges

- Project completion on time and within budget

- Security Issues Cannot be Foreseen since some of the most frequent causes of occupational fatalities include failure of personal protective equipment, electric shock, falls from great heights, injuries from repetitive action, and trench collapse.

- It allows site managers to provide their employees with training in real time while simultaneously reducing the frequency of workplace injuries and the associated expenditures on medical care.

- A major problem is the lack of qualified workers.

Also check out: The Future of Architecture: How Will it Evolve And What to Expect?

6. Blockchain

Blockchain allows for data ownership transparency. As a result, collaboration and trust between parties will grow, and data will be more freely shared. Through its immutable ledger, the blockchain can increase transparency for each type of agreement and transaction throughout a construction project. It can result in a more efficient procurement process, lowering the high degree of dispersion and complexity of large projects. The origin of the resources can eliminate waste & push product quality and services forward with high accountability. Such technologies can improve predictability, both in terms of procurement and overall project delivery.

Blockchain has the potential to become the sole source of information for all elements of a construction project when combined with Building information modeling (BIM). Such a framework may facilitate an asset's design, building, operation, and maintenance over its entire lifecycle, serving as its trustworthy digital twin.

Applications

- It allows the transfer of digital data that is inherently unique and cannot be changed, copied, or replicated.

- Cryptographic codes protect the information's integrity and security.

- The blockchain's participants independently confirm and verify any modifications that are made there. As a result, there is no requirement for third-party authentication or authorization.

Challenges

- Regarding the legality of the data uploaded to the blockchain, data authenticity will continue to be an issue, although wearable technology, biometrics, drones, and sensing technologies may limit the potential for fraud.

- Continuous internet access or ways of offline data storage, while connectivity can be established, are essential whenever construction is taking place. Keeping a duplicate of the blockchain requires a sizable amount of storage space.

7. Augmented Reality (AR) and Virtual Reality (VR)

%20and%20Virtual%20Reality%20(VR).jpg?width=768&height=432&name=Augmented%20Reality%20(AR)%20and%20Virtual%20Reality%20(VR).jpg)

Augmented Reality (AR) and Virtual Reality (VR) technologies are being increasingly adopted in the construction industry for purposes such as visualizing designs, training workers, and creating immersive experiences for clients. AR can overlay digital information onto the real-world environment, while VR creates a fully simulated environment. Imagine a construction worker equipped with Google Glass receiving real-time updates while on the job. With AR technology, workers can receive safety alerts if they show signs of fatigue, prompting them to take a break. AR can also provide instant access to data like temperature and pressure, empowering workers to spot issues early on. This technology enhances safety and productivity by delivering crucial information directly to the worker's field of view.

Applications:

- Visualising and experiencing architectural designs before construction begins.

- Training workers on equipment operation and safety procedures in a risk-free virtual environment

- Allowing clients to "walk through" a building before it's built for better understanding and feedback

Challenges:

- Ensuring the accuracy and fidelity of virtual models and environments

- Integrating AR/VR technologies seamlessly with existing workflows and systems

- Providing adequate training for construction professionals to utilize these technologies effectively

8. Robotics

Robotics is transforming construction sites, with robots being used for tasks such as bricklaying, material handling, demolition, and even 3D printing of entire structures. Automated construction processes can improve efficiency, reduce manual labour, and enhance safety.

Applications:

- Autonomous bricklaying robots that can construct walls with high precision and speed

- Robotic material handling and transportation systems for improved logistics on construction sites

- Robotic demolition machines that can selectively deconstruct structures with precision and minimal human intervention

Challenges:

- Integrating robotic systems with existing construction processes and workflows

- Ensuring the safety of human workers operating alongside robots on construction sites

- Training and upskilling construction professionals to operate and maintain robotic systems

9. Wearable Technology

Wearable devices, such as smart helmets, safety vests, and exoskeletons, are being adopted in the construction industry to enhance worker safety, monitor health and fatigue, and improve productivity.

Applications:

- Smart helmets with built-in sensors and cameras for monitoring worker safety and site conditions

- Exoskeletons that augment human strength and endurance, reducing strain and injuries

- Wearable devices that track worker movements, vitals, and fatigue levels for better resource management

Challenges:

- Ensuring the reliability and accuracy of data collected from wearable devices

- Addressing privacy concerns related to worker monitoring and data collection

- Providing adequate training and support for workers to use wearable technologies effectively

10. Digital Twins

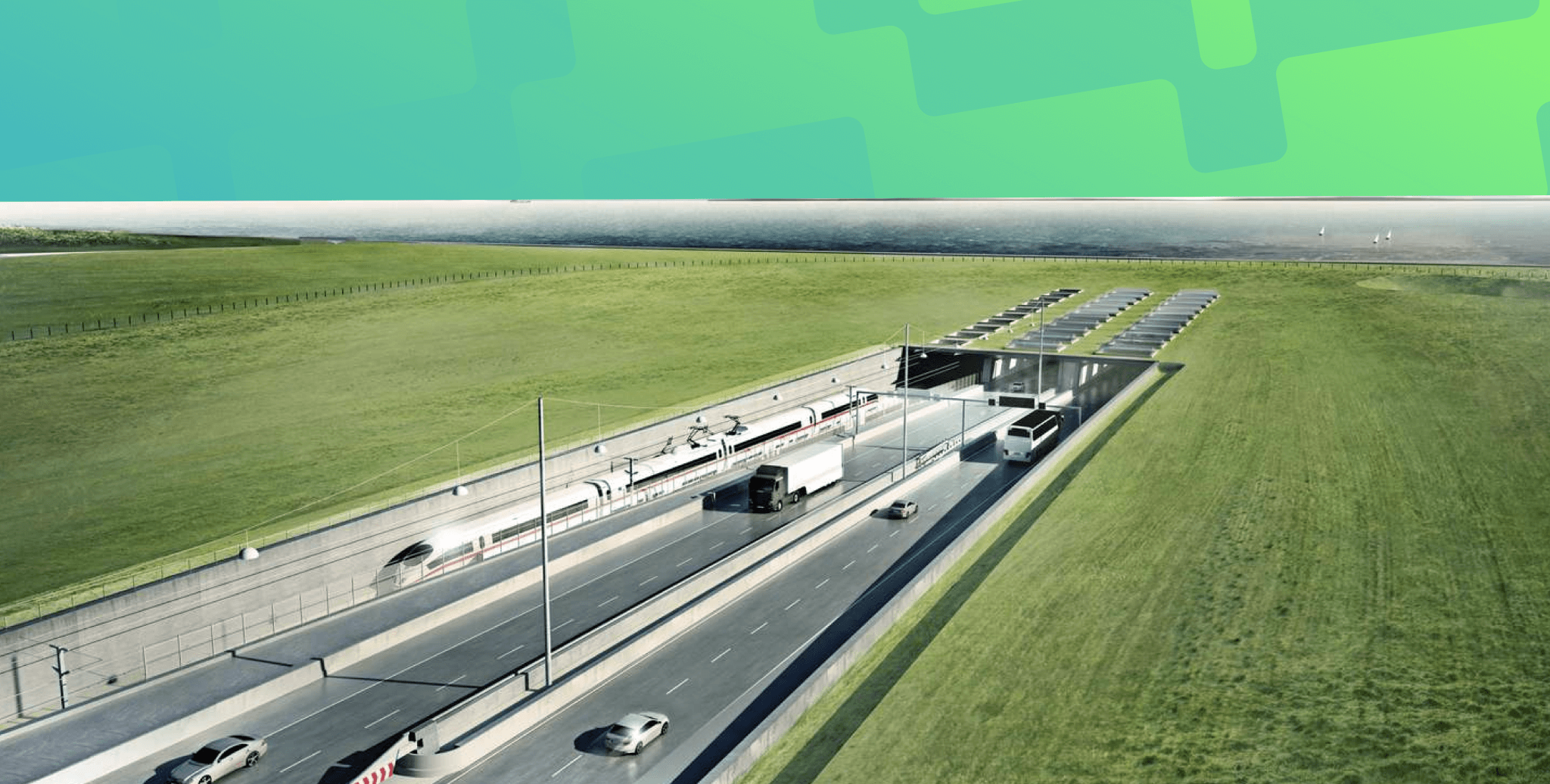

Digital twins are virtual representations of physical assets, processes, or entire construction projects. They leverage data from various sources, such as sensors, BIM models, and IoT devices, to create a comprehensive digital model that can be used for simulation, analysis, and optimization.

Applications:

- Creating a virtual replica of a construction project to simulate and optimize various scenarios before physical construction begins

- Monitoring and analyzing the performance of a completed structure throughout its lifecycle

- Improving maintenance and repair processes by leveraging data from the digital twin

Challenges:

- Integrating and synchronizing data from multiple sources to create accurate digital twins

- Ensuring the security and integrity of the data used to create and update digital twins

- Providing intuitive interfaces and tools for construction professionals to interact with and leverage digital twins effectively

The future of construction technology involves creating smarter, safer, and more sustainable built environments by integrating innovative digital tools and solutions.

Why is The Traditional Brick-and-Mortar Industry Reshaping?

There are several factors to it:

1. Evolving Client Expectations

Clients today are more informed and have higher expectations than ever before. They demand innovative, customised solutions for residential, commercial, and industrial projects.

2. Advancements in Technology

The rapid development and affordability of smart sensors, software, and hardware are revolutionising construction processes. Emerging technologies like augmented reality (AR), virtual reality (VR), drones, robotics, and additive manufacturing (3D printing) are enhancing efficiency, precision, and productivity across the industry.

3. The Rise of Construction Startups

Tech-driven market shifts have created opportunities for startups to disrupt traditional construction practices. These innovators are driving significant advancements in materials, automation, and project management.

4. A New Generation of Tech-Savvy Professionals

A new wave of professionals, more proficient with digital tools and emerging technologies, is entering the workforce. This transformation presents exciting career opportunities for those eager to merge creativity with construction.

5. Supportive Regulatory Frameworks

Governments worldwide are implementing stricter energy efficiency and carbon emission regulations to combat climate change. With construction accounting for 38% of global energy-related CO₂ emissions, digitalisation presents an opportunity to minimise environmental impact while ensuring compliance with evolving sustainability standards.

In Conclusion

The construction industry is undergoing a massive transformation thanks to emerging technologies. These technologies are bringing greater efficiency, productivity, and safety to the construction process. By leveraging automation, artificial intelligence, robotics, and other cutting-edge technologies, construction companies can save time and money, reduce waste, and enhance overall project outcomes. While some of these technologies are still in their infancy, they show great promise for the future of construction. As the industry continues to evolve, we can expect to see even more exciting developments in the years ahead.

If you’re a professional in today’s construction industry and are looking to get started with some of these technological trends, do check out Novatr’s Master Computational Design Course for Real-World Application, BIM Professional Course for Architect V2.0 and BIM Professional Course for Civil Engineers. Start upskilling today!

Also, don’t forget to check our Resources page for more guidance.

Thanks for connecting!

Thanks for connecting!

-1.png)

.png)

.jpg)