As buildings grow more intelligent and more complex, facility managers are expected to do much more than just fix things when they break. They are now responsible for ensuring that entire MEP systems, encompassing mechanical, electrical, and plumbing, operate smoothly from day one. And that is where BIM MEP integration comes in.

With tools like Revit MEP and BIM MEP software, facility management has evolved from reactive maintenance to proactive oversight using data-rich models. Understanding MEP BIM modelling is no longer optional for facility managers; it is essential. It enables them to visualise and access every part of a building’s infrastructure with precision, making decision-making smarter and faster.

The integration of 3D BIM technology with MEP infrastructure allows real-time collaboration between MEP engineers, architects, and facility teams. In short, BIM MEP bridges the gap between construction and long-term operations, bringing a wealth of benefits for maintenance, planning, and budgeting. In this blog, we will explore how facility managers can harness this synergy for more efficient building management and better asset performance.

What Is BIM MEP Integration?

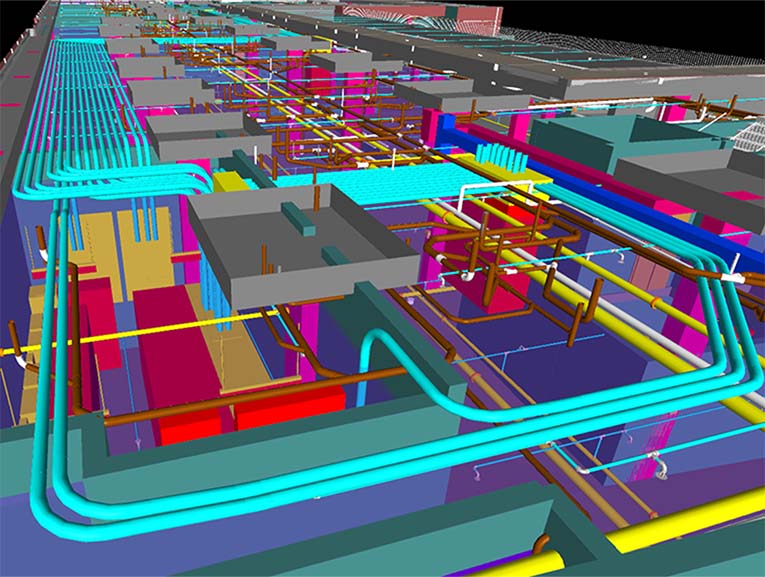

BIM MEP integration refers to the process of embedding MEP systems within a building's digital model using Building Information Modelling (BIM) software, such as Revit MEP. It creates a unified BIM 3D model that includes all MEP works in construction, allowing every system to be viewed, analysed, and managed from one source of truth.

This integration brings together architecture, structure, and MEP design into a coordinated platform. By using MEP drafting software, engineers can design and document services with more accuracy and fewer conflicts. The end product is not just a visual 3D layout; it is a rich dataset containing all the specs, performance data, and lifecycle history of MEP projects.

For facility managers, having access to this comprehensive data through BIM MEP services means better planning, fewer surprises, and more informed decision-making.

How Does BIM Help in Managing MEP Systems?

The real value of BIM MEP lies in how it supports day-to-day operations. With MEP BIM modelling, facility managers can access all system details without ripping open walls or digging through blueprints. Need to find the location of a faulty valve or a junction box? The BIM 3D model shows exactly where it is.

Moreover, 3D BIM technology supports clash detection during design and construction, reducing future maintenance headaches. It also makes routine tasks like HVAC servicing or lighting upgrades more predictable.

MEP software tools connected to BIM MEP software can also monitor system performance, triggering alerts when something is off. By integrating MEP in architecture, facility managers can better understand how spatial design impacts system performance and occupancy comfort.

Why Is BIM Critical for Facility Managers Post-Construction?

Once the construction crew packs up and leaves, facility managers become the building’s new caretakers. That handover often comes with thousands of documents, but a single MEP BIM modelling file replaces all that clutter.

BIM MEP gives facility teams direct access to specifications, equipment details, and manufacturer data embedded into the model. With the help of MEP design software, these files can be updated and maintained throughout the building’s lifecycle.

Instead of reacting to issues, managers can proactively schedule maintenance, track asset depreciation, and plan upgrades using insights derived from BIM software. By linking MEP infrastructure to digital platforms, the post-construction phase becomes far more manageable.

This kind of insight is especially crucial for large, complex buildings, such as hospitals, universities, and airports, where system downtime is both costly and potentially dangerous.

What Benefits Does BIM Provide in Maintenance and Operations?

The operational phase of a building's life can last for decades, and it is here that BIM MEP services truly excel. Some key benefits include:

-

Quick access to asset data: Managers no longer need to guess specifications—BIM 3D model data includes serial numbers, maintenance schedules, and even service history.

-

Efficient space management: MEP design components can be analysed in real time to make better use of available space.

-

Enhanced energy performance: MEP software linked with monitoring tools can identify energy wastage or inefficiencies early.

-

Improved emergency preparedness: In a crisis, knowing the layout of MEP infrastructure enables faster and more effective responses.

-

Streamlined documentation: With digital updates, the MEP in the architecture context remains current even as upgrades occur.

With the right BIM MEP software, facility managers can shift from routine tasks to more strategic roles, saving time, money, and resources in the process.

How Can Facility Managers Use BIM for Predictive Maintenance?

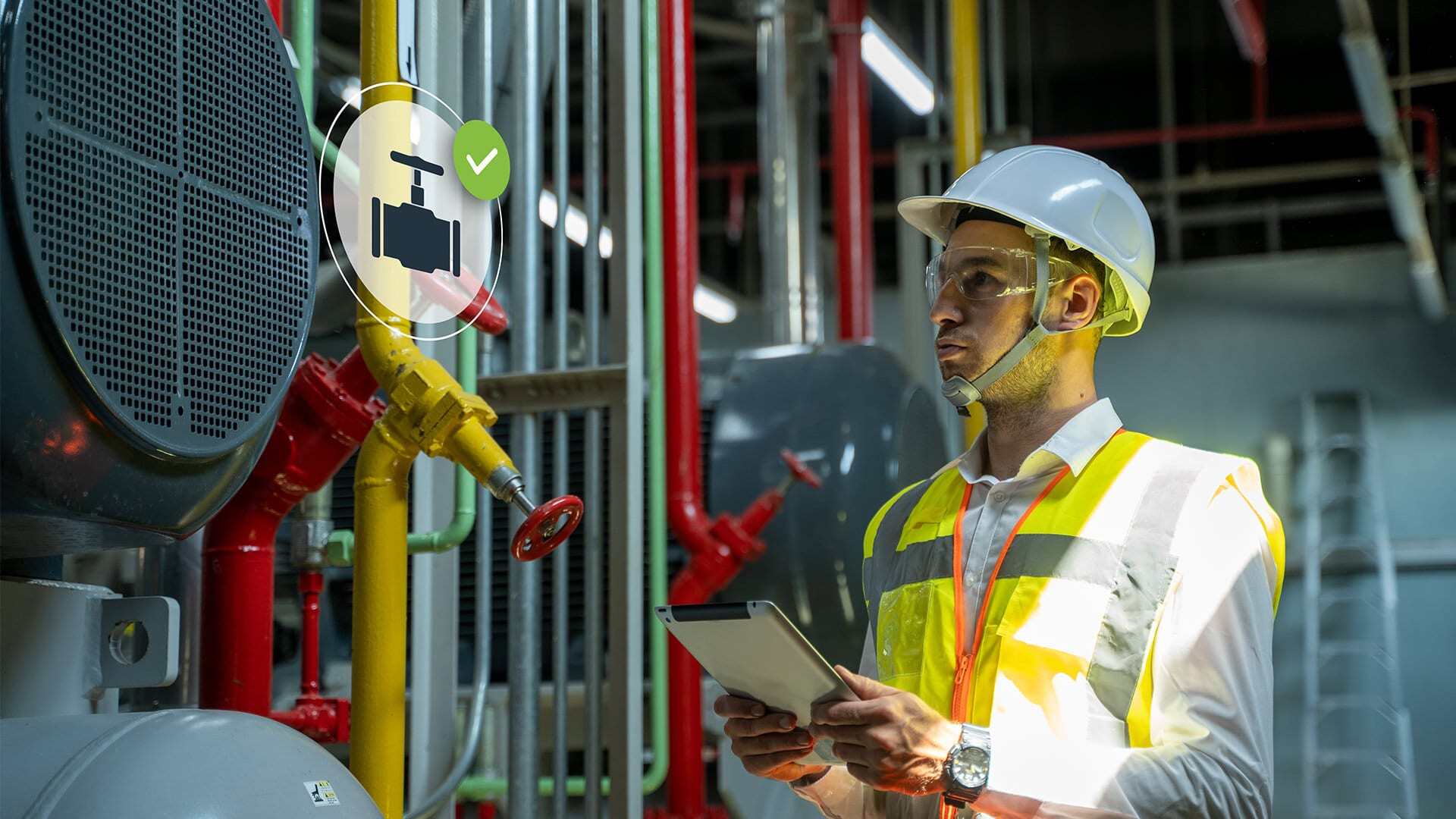

Traditional maintenance waits for things to break. Predictive maintenance, powered by BIM MEP, utilises data to act before issues arise.

By integrating sensors and IoT tools into MEP systems and connecting them to BIM MEP software, facility managers can monitor real-time data, such as temperature, pressure, and flow rates. Any unusual behaviour triggers alerts, prompting inspections before failures occur.

Revit MEP software can be linked with building automation systems (BAS) to keep this data dynamic and accessible. The historical information stored within the BIM 3D model helps identify trends and predict the lifespan of equipment.

Predictive maintenance not only reduces downtime but also extends the longevity of assets. Over time, this saves huge costs in repairs, replacement, and energy.

What Are the Challenges of Adopting BIM in Facility Management?

Despite its many advantages, implementing BIM MEP modelling in facility management is not without challenges:

-

Cost and training: Tools like Revit MEP and MEP drafting software require significant investment and skilled staff to manage them effectively.

-

Data overload: With so much information in a BIM 3D model, filtering out what is relevant for day-to-day operations can be tricky.

-

Integration with existing systems: Legacy MEP design software or paper-based workflows may not sync easily with modern BIM software.

-

Changing mindsets: Some professionals in the MEP industry resist change, opting for the familiar over the digital.

However, these hurdles are increasingly being addressed through user-friendly platforms, targeted training, and broader adoption of MEP BIM modelling in education and practice.

Conclusion

Facility management is no longer about reacting to issues with tools and elbow grease. Today, it is about making data-driven decisions, reducing operational costs, and extending the life of building systems—all made possible through BIM MEP integration.

By embracing 3D BIM technology, facility managers gain a significant competitive advantage. From streamlined maintenance to predictive analytics, the benefits are too impactful to ignore. With support from tools like Revit MEP software, MEP design software, and BIM MEP services, facility teams can manage assets with far greater accuracy and confidence.

Yes, there are challenges. But the return on investment, both financially and operationally, is clear. As the MEP construction management landscape evolves, the role of facility managers is also transforming. And those who understand and leverage MEP BIM modelling will be the ones leading the charge. Among the best options, the BIM Professional Program for MEP Engineers by Novatr stands out the most. For the latest updates, tools, and insights into the MEP and BIM industry, explore Novatr's Resource Page.

Was this content helpful to you

.jpeg)

.png)